Non-Destructive Testing (NDT) Instruments for Accurate Inspections

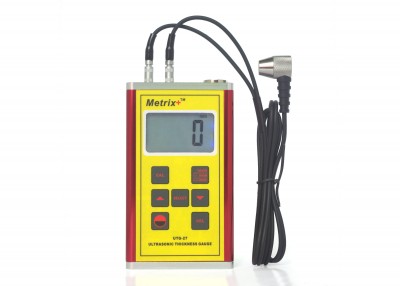

We are Metrix Plus, specializing in the provision of the most portable Non-Destructive Testing (NDT) instruments that provide precise measurements for important parameters like coating thickness, gloss finish, surface roughness, the thickness of samples, as well as hardness measurements. Our instruments are engineered to be easy-to-use, light and efficient, providing precise and reliable results, without causing any harm to the materials being examined. No matter if you're in manufacturing quality control or materials testing or quality control, our NDT solutions offer reliable results for your tasks.

Being one of the top NDT equipment manufacturers in India, Metrix Plus is dedicated to supplying only the most advanced tools designed to your specific testing requirements. Our vast selection of instruments for non-destructive testing conforms to the most stringent industry standards, which ensures reliability and accuracy regardless of the difficult conditions.

Benefits of NDT Equipment

Non-destructive Testing materials without destroying the surface.

Accurate provides precise measurements with good repeatability.

Portable It is easy to carry and ergonomic to use.

Cost-effective: Saves post-manufacturing quality control costs, by identifying issues earlier.

Enhanced safety: Identifies any flaws that could cause failures or accidents.

Efficiency Testing is quick and without causing interruption to workflows.

Applications of NDT Instruments

Manufacturing & Quality Control is used to ensure the integrity of products and conformity with industry standards.

Construction Assesses the state of the infrastructure.

Aerospace inspects components for fatigue and cracks.

Automotive Finds out if there are any imperfections in parts of vehicles.

Oil & Gas Monitoring pipelines and equipment to detect corrosion.

Energy checks turbines and power plants for any issues.

Marine evaluates the hulls of ships and offshore rigs for structural strength and integrity.

Uses of NDT Instruments

Test of Material Measures thickness, roughness, hardness, gloss, and many other parameters to ensure proper surface finish.

Structural inspections Finds out if there are any problems with machinery and infrastructure.

Quality Assurance: Ensures consistent product quality.

Preventive Maintenance is a way to identify issues prior to prevent breakdown or critical failures.

FAQs Related to NDT Instruments

What is Non-Destructive Testing (NDT)?

NDT equipment examines the material without destroying the surface, to measure various properties like thickness, roughness, hardness, gloss, flaw detection, etc.

What industries would benefit by NDT?

Most manufacturing industries doing Quality Assurance of products benefit from NDT testing, like automotive, manufacturing, aerospace, oil and gas, construction and energy as well as marine industries.

What are the most popular kinds that NDT tools are?

Coating thickness gauges, Surface roughness testers, Ultrasonic gauges, Hardness Testers, Gloss Meters, are the common ones.

What makes portability so important in NDT equipment?

Testing on-site is possible which is ideal for remote areas or companies with field testing requirements.

How precise are the instruments of NDT?

They offer accurate, real-time data for reliable measurements to ensure the ability to meet compliance.

Can instruments for NDT be utilized for all kinds of types of materials?

Yes, they can work with various materials like metals, plastics and composites ceramics, concrete, etc.

Are NDT instruments expensive?

Costs can vary however they can be efficient in avoiding costly repair and downtime.

How do I select the best NDT device?

Make your selection based on the material requirements for testing, the test needs, and the conditions. Consult with experts such as Metrix Plus helps ensure the best choice.

A list of NDT instrument manufacturers from India

Metrix+ stands at the leading edge, offering unbeatable solutions to meet your needs for measurement and testing with accuracy and reliability.